Table of Contents

- What is Annealed Glass? Understanding the Foundation of All Residential Glazing

- Tempered Glass Explained: Why Building Codes Require It in Doors, Bathrooms, and Low Windows

- Laminated Glass: Superior Safety, Security, Soundproofing, and UV Protection in a Single Pane

- Annealed vs. Tempered vs. Laminated: A Direct Comparison of Performance, Cost, and Applications

- Case Studies: Choosing the Right Glass for Portland & Vancouver Area Homes

- How Modern Windows Combine Glass Types for Maximum Performance

- Key Takeaways

Every window and door in your home contains glass—but not all glass is created equal. While they may look identical from the curb, the type of glass protecting your family has a profound impact on safety, security, energy efficiency, and even noise levels inside your home. If you’re building, remodeling, or replacing windows in the Portland or Vancouver area, you’ve likely encountered terms like “tempered,” “laminated,” and “annealed” glass. Understanding the differences isn’t just about making an informed purchase—it’s about compliance with building codes and protecting your loved ones from preventable injuries. According to the National Safety Council, falls are a leading cause of unintentional injury-related deaths at home, and unsafe glass can turn a minor accident into a serious medical emergency. In this comprehensive guide, we’ll break down the science, safety standards, and real-world applications of the three primary types of residential glass. You’ll learn:

- How each glass type is manufactured and what makes it unique

- Which federal safety codes dictate where each type must be used

- The performance differences in strength, sound insulation, UV protection, and security

- Practical recommendations for common scenarios like patio doors, bathrooms, and skylights

By the end, you’ll have the technical knowledge to make confident decisions and ensure your home is both beautiful and code-compliant.

What is Annealed Glass? Understanding the Foundation of All Residential Glazing

Annealed glass is the most basic form of glass produced and serves as the starting point for tempered and laminated glass. While cost-effective, its dangerous breakage pattern makes it unsuitable for most modern residential applications.

The Float Glass Process: How Annealed Glass is Made

Modern annealed glass is produced using the “float glass” process, perfected by Sir Alastair Pilkington in the 1950s. This revolutionary manufacturing method involves three critical stages: Melting and Refining: Raw materials including silica sand, soda ash, and limestone are melted in a furnace at approximately 2,800°F. At this extreme temperature, these materials combine to form molten glass. Floating: The molten glass is poured onto a shallow bath of molten tin in a controlled atmosphere. Because glass is highly viscous and doesn’t mix with tin, it floats on the surface. Gravity naturally pulls the glass into a perfectly flat, uniform sheet with consistent thickness. Annealing: The ribbon of glass moves through a long cooling chamber called a lehr, where it’s allowed to cool at a slow, controlled rate. This critical “annealing” step relieves internal stresses that would otherwise cause the glass to be unstable and fracture easily.

Physical Characteristics: Strength and Workability

Annealed glass has specific performance characteristics that define its applications:

- Strength: It has a typical surface compression of less than 3,500 pounds per square inch (psi) and a modulus of rupture (MOR) of approximately 6,000 psi

- Workability: It can be easily cut, drilled, and polished after manufacturing, making it ideal for custom fabrication work

- Cost: It’s the least expensive glass option, serving as the baseline for pricing comparisons

The Critical Safety Issue: Why Annealed Glass is Dangerous

Where Annealed Glass Can Still Be Used Legally

Despite its limitations, annealed glass has legitimate applications in protected areas:

- Small window panes in protected, low-traffic areas (such as traditional divided-lite windows away from doors and floors)

- As a component within insulated glass units (IGUs) when paired with safety glass in non-hazardous locations

- Picture frames, decorative applications, and tabletops when not subject to impact

- Upper-story windows where the glass is far from walking surfaces and doors

The Regulatory Context: Why Codes Exist

The U.S. Consumer Product Safety Commission (CPSC) established mandatory safety standards—specifically 16 CFR Part 1201—to prevent injuries from broken annealed glass in hazardous locations. This federal regulation exists because of documented injuries and deaths caused by impacts with unsafe glass. Understanding where annealed glass is prohibited is essential for any homeowner undertaking window or door replacement.

Tempered Glass Explained: Why Building Codes Require It in Doors, Bathrooms, and Low Windows

Tempered glass is heat-treated to be 4-5 times stronger than annealed glass and shatters into small, harmless pieces. It is the minimum required safety glazing in all “hazardous locations” as defined by the International Building Code (IBC).

The Tempering Process: Creating Safety Through Heat and Stress

Tempered glass starts as standard annealed glass that’s been cut to its final size—and this is crucial because tempered glass cannot be modified after the heat treatment process. Any holes, edge work, or custom shaping must be completed before tempering begins. The glass is then heated in a tempering oven to over 1,100°F, bringing it to its softening point. Immediately upon exiting the furnace, the glass surface is rapidly cooled with high-pressure air jets in a process called “quenching.” This rapid cooling cools the outer surfaces much faster than the center, creating a balanced state of high surface compression and interior tension. This induced stress—surface compression exceeding 10,000 psi according to Fenestration and Glazing Industry Alliance (FGIA) standards—is what gives tempered glass its exceptional strength and unique safety characteristics.

Safety Performance: The Pebble Effect

When tempered glass breaks, the stored energy releases instantly, causing the entire pane to fracture into small, pebble-like pieces with relatively dull edges. This “dicing” fracture pattern dramatically reduces laceration risk compared to the large, sharp shards produced by annealed glass. The difference is not just academic—it’s life-saving. Tempered glass meets the CPSC 16 CFR Part 1201 impact safety standard, which is mandatory for all hazardous locations. Every piece of tempered glass must have a permanent, acid-etched label identifying the manufacturer and confirming standard compliance.

Thermal Resistance: Handling Temperature Extremes

The tempering process increases the glass’s ability to withstand thermal stress by up to 400°F. This makes tempered glass essential for applications with significant temperature differentials, such as:

- Shower doors exposed to hot water

- Glass near cooking surfaces

- Exterior doors in climates with extreme seasonal temperature swings

The Spontaneous Breakage Phenomenon

While extremely rare, tempered glass can occasionally shatter without any obvious external impact. The primary cause is microscopic nickel sulfide (NiS) inclusions—a byproduct of the manufacturing process. These inclusions can change volume over time, creating internal stress that eventually exceeds the glass’s tension and causes spontaneous fracture. While this is a known phenomenon in the glass industry, the occurrence rate is very low, and the safety benefits of tempered glass far outweigh this risk.

Where Building Codes REQUIRE Tempered Glass

The International Building Code (IBC Section 2406.4) defines specific “hazardous locations” where safety glass is mandatory:

| Hazardous Location | Code Requirement |

|---|---|

| All swinging, sliding, bifold, and storm doors | Safety glass mandatory |

| Sidelites (fixed panels within 24″ arc of door) | Safety glass mandatory |

| Large, low windows (bottom <18", top >36″, area >9 sq ft) | Safety glass mandatory |

| Stairways (glazing within 60″ of bottom tread) | Safety glass mandatory |

| Bath/shower/pool enclosures (bottom edge <60" above floor) | Safety glass mandatory |

These requirements are not optional—they’re enforceable code standards designed to protect occupants from preventable injuries.

Real-World Applications and Cost

Tempered glass is the standard choice for:

- Patio and sliding doors

- Shower and bathtub enclosures

- Bathroom windows

- Entry door sidelites

- Low-level windows in living areas

The cost is approximately 2x that of annealed glass, making it an affordable safety investment for code-required locations.

Laminated Glass: Superior Safety, Security, Soundproofing, and UV Protection in a Single Pane

Laminated glass consists of two or more glass layers bonded with a durable plastic interlayer. It offers the highest level of safety, security, and acoustic performance, making it ideal for skylights, high-security applications, and noise reduction.

Construction and Interlayer Technology

Laminated glass is manufactured by bonding two or more glass lites together with a flexible interlayer under heat and pressure in an industrial autoclave. The choice of interlayer material significantly impacts the glass’s performance characteristics: Standard PVB (Polyvinyl Butyral): The most common interlayer, offering excellent safety performance, outstanding UV blocking, and good sound dampening properties. Acoustic PVB: A specially formulated interlayer designed to reduce mid-to-high frequency noise, including voices and traffic sounds. This specialized material is ideal for homes in noisy urban environments. SentryGlas® (SGP Ionoplast): A much stronger and more rigid interlayer than PVB, offering superior structural performance, edge stability, and optical clarity. It’s commonly used in hurricane-rated glazing, structural glass railings, and overhead applications where strength is critical.

The “Safety Barrier” Advantage

This post-breakage integrity is essential for overhead glazing applications like skylights, where falling glass shards could cause serious injuries to occupants below. It’s also critical for security applications, where maintaining a barrier prevents easy entry even after the glass is broken.

Security Performance: Protection Against Break-Ins

The interlayer makes laminated glass extremely difficult to penetrate. While a burglar can break the glass, they cannot easily push through it. Standard laminated glass resists “smash and grab” burglaries, and multi-ply laminated glass can meet ballistic and blast resistance standards for high-security applications. The global security glass market is projected to grow significantly, reflecting rising demand for residential protection. Homeowners increasingly recognize that laminated glass provides peace of mind beyond basic safety compliance.

Acoustic Performance: Creating Quieter Homes

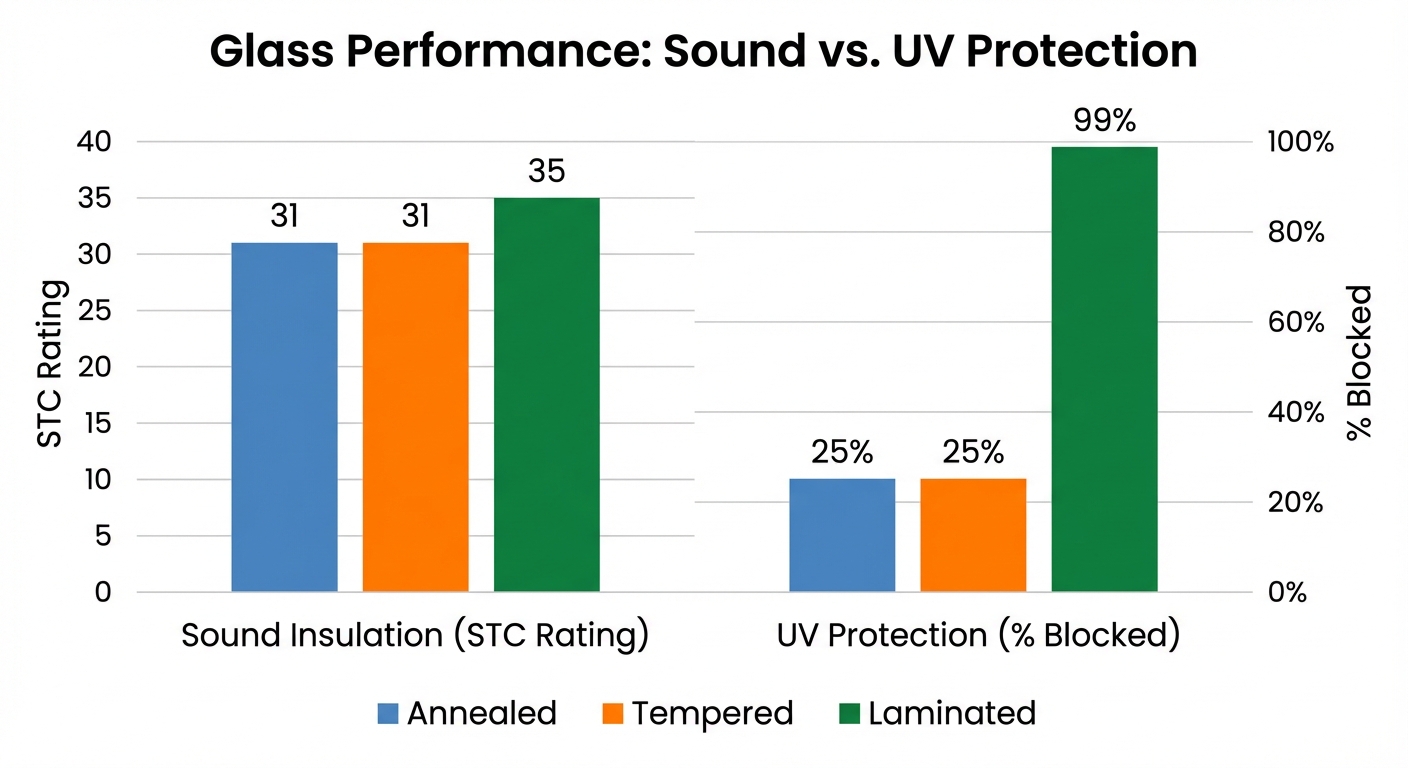

The flexible interlayer acts as a vibration dampener, disrupting sound wave transmission through the glass. The performance difference is substantial:

- Standard ¼” monolithic glass: STC (Sound Transmission Class) ~31

- Laminated ¼” glass: STC ~35+

UV Protection: Preserving Your Interior

Standard PVB interlayer blocks over 99% of harmful UV radiation up to 380 nanometers. This protection prevents fading of interior furnishings, flooring, and artwork without reducing visible light or creating the dark, tinted appearance of some window films. For homes with valuable interior finishes or art collections, laminated glass provides museum-quality UV protection as a built-in feature.

Cost and Mandatory Applications

Laminated glass is the most expensive option, typically costing 2.5-3x that of annealed glass. However, it’s mandatory in certain critical applications: Required by Code:

- Skylights and sloped overhead glazing (IBC Section 2405.3 requires laminated glass as the bottom lite to prevent falling shards)

Ideal Upgrade Applications:

- High-security windows and doors

- Noise-sensitive areas (bedrooms facing traffic, home offices)

- Spaces with valuable furnishings requiring UV protection

- Glass canopies and atriums

Annealed vs. Tempered vs. Laminated: A Direct Comparison of Performance, Cost, and Applications

Understanding the technical differences between glass types helps you make informed decisions for your specific needs and budget.

Comprehensive Comparison

| Property | Annealed | Tempered | Laminated |

|---|---|---|---|

| Manufacturing | Slow, controlled cooling of float glass | Rapidly heated & quenched to create surface compression | Two+ glass lites bonded with plastic interlayer under heat/pressure |

| Strength | Baseline (1x). MOR ~6,000 psi | High (4-5x). Surface compression >10,000 psi | Similar to annealed but with high post-breakage integrity |

| Breakage Pattern | Large, sharp, dangerous shards | Small, pebble-like, relatively harmless pieces | Cracks but fragments adhere to interlayer |

| Safety Level | Low (not safety glass) | High (meets CPSC 16 CFR 1201) | Very High (meets CPSC + provides post-breakage barrier) |

| Cost (Relative) | $ (baseline) | $$ (~2x annealed) | $$$ (~2.5-3x annealed) |

| Sound Insulation | Poor (STC ~31) | Poor (same as annealed) | Excellent (STC ~35+) |

| UV Protection | Minimal (<25%) | Minimal (<25%) | Excellent (>99% with PVB) |

| Can Be Modified After Production? | Yes (cut/drilled) | No (must be cut before tempering) | No (cut before lamination) |

| Post-Breakage State | Opening fully exposed | Opening fully exposed (pebbles fall out) | Opening sealed by interlayer barrier |

| Primary Benefit | Low cost, customizability | Impact safety, thermal resistance | Safety, security, acoustic performance, UV protection |

Decision-Making Framework

Use Tempered Glass When:

- Building codes require safety glass in the location

- Budget is moderate

- Primary concern is impact protection and thermal resistance

- Application is in hazardous locations (doors, bathrooms, low windows)

Upgrade to Laminated Glass When:

- Security is a priority (first-floor windows, vulnerable entry points)

- Noise reduction is needed (rooms facing busy streets)

- UV protection is important (rooms with valuable furnishings)

- Overhead applications require extra safety (skylights, glass ceilings)

- Post-breakage barrier is critical (maintaining security after impact)

Never Use Annealed Glass When:

- Location is defined as hazardous per IBC Section 2406.4

- Glass is within 60″ of a walking surface

- Glass is in or near a door

- Glass is in a bathroom or shower enclosure

- Glass is in a stairway or landing area

Case Studies: Choosing the Right Glass for Portland & Vancouver Area Homes

Let’s examine real-world scenarios that demonstrate how to apply building code knowledge and performance priorities to common glass replacement projects.

Case Study 1: Replacing a Sliding Patio Door Facing a Busy Street

The Scenario: A homeowner in Southeast Portland is replacing an old, inefficient sliding glass door. The door faces Division Street, with constant traffic noise affecting the living room and dining area. Code Requirement: IBC Section 2406.4 mandates safety glass for all sliding doors. This is non-negotiable—using annealed glass would violate code and create a serious safety hazard. Standard Solution: Tempered glass meets the code requirement and is the most cost-effective choice. It provides impact safety and thermal resistance. Recommended Upgrade: An insulated glass unit (IGU) with an exterior laminated glass lite and interior tempered lite provides superior performance:

- Meets all safety code requirements (tempered interior lite)

- Dramatically reduces traffic noise (STC improvement from ~31 to ~35+)

- Blocks 99% of UV rays to protect hardwood flooring and furniture

- Adds security against break-ins (laminated exterior resists penetration)

Why It Matters: Portland and Vancouver homeowners value both safety and livability. This upgrade delivers code compliance while creating a more comfortable, quieter living space. The additional investment pays dividends in reduced noise pollution and interior preservation.

Case Study 2: Bathroom Remodel with Large Shower Window

The Scenario: A Vancouver homeowner is renovating their master bathroom and wants to install a large picture window inside the shower enclosure to enjoy garden views while bathing. Code Requirement: Safety glass is mandatory for any glazing in shower walls where the bottom edge is less than 60 inches above the floor. This requirement exists because shower floors are slippery, and falls against glass are common bathroom injuries. Recommended Solution: Tempered glass is the only acceptable choice for this application. Here’s why:

- Meets CPSC 16 CFR 1201 safety standards (mandatory)

- Withstands thermal shock from hot water (400°F differential tolerance)

- Provides safe breakage pattern to protect bathers

- Can be customized with frosted, etched, or textured patterns for privacy

Why It Matters: Using non-tempered glass in a shower is both dangerous and illegal. During a home sale, building inspectors will flag non-compliant glass, potentially derailing the transaction. More importantly, the safety risk to family members is unacceptable. This is a non-negotiable code requirement that protects lives.

Case Study 3: Adding a Skylight in a Rainy Climate

The Scenario: A homeowner in West Linn wants to add a skylight to their kitchen to increase natural light in a space that currently feels dark and enclosed. Code Requirement: IBC Section 2405.3 requires laminated glass as the bottom-most lite in skylights and sloped glazing. This ensures that if the glass breaks—from a falling tree branch, hail, or other impact—the fragments will remain in place rather than falling on occupants below. Recommended Solution: An IGU combining an exterior tempered glass lite and interior laminated glass lite represents industry best practice:

- Exterior tempered glass provides superior impact resistance against hail and debris

- Interior laminated glass ensures fragments won’t fall if broken (code compliance)

- IGU construction provides energy efficiency

- Meets all safety requirements for overhead glazing

Why It Matters: In the Pacific Northwest’s rainy climate with frequent storms and overhanging trees, skylights face higher risk of impact damage. The consequences of broken glass falling from a ceiling-mounted skylight can be severe—ranging from cuts and lacerations to serious head injuries. Laminated glass is not just recommended; it’s essential for overhead safety and is required by code.

How Modern Windows Combine Glass Types for Maximum Performance

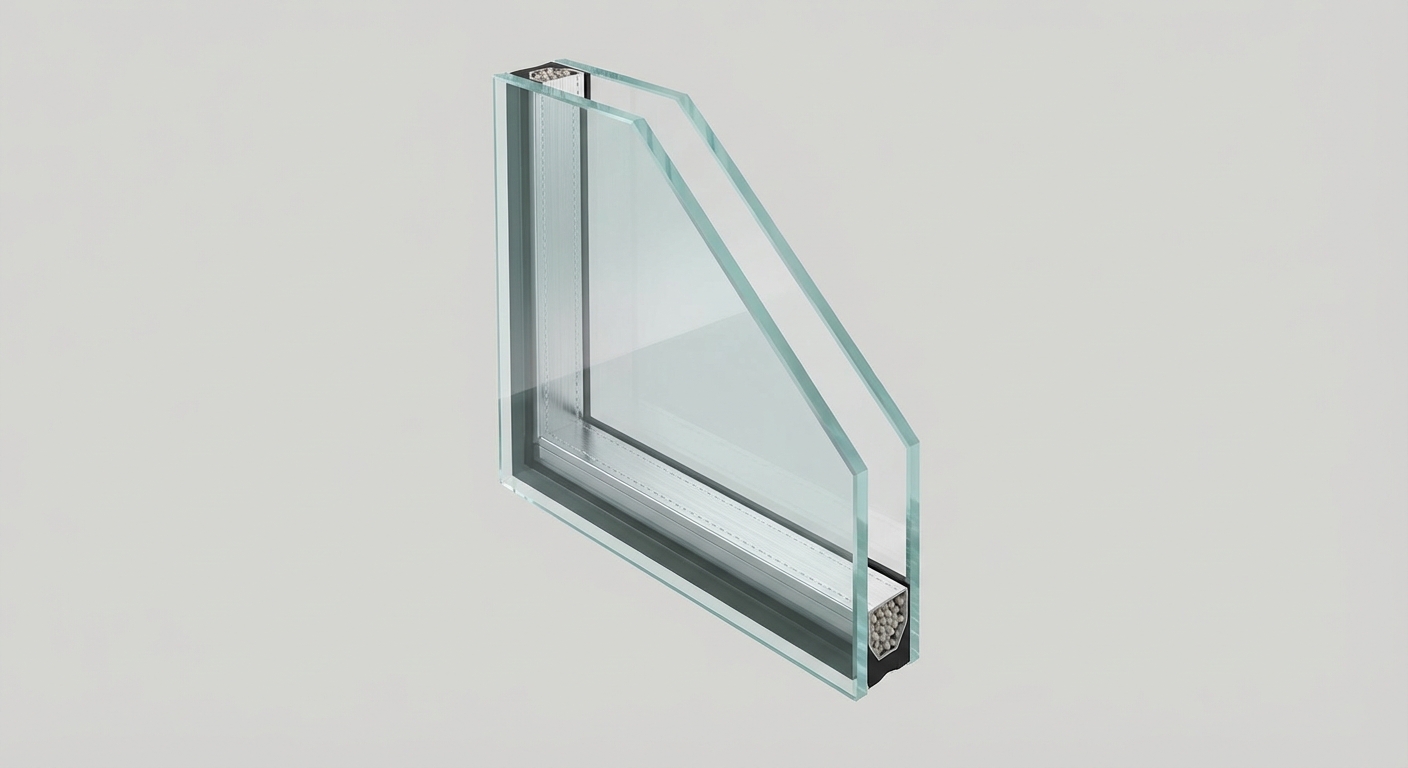

Most contemporary windows don’t use a single pane of glass. Instead, they use Insulated Glass Units (IGUs) that combine different glass types and advanced coatings to optimize safety, energy efficiency, and comfort.

What is an Insulated Glass Unit?

An IGU consists of two or three panes of glass separated by a sealed air or gas-filled space. The space between panes is maintained by a spacer bar around the perimeter, which is sealed to prevent moisture infiltration and gas escape. Annealed, tempered, and laminated glass are the components used to build these units. The beauty of IGUs is that they can be customized by combining different glass types to address specific performance needs.

Strategic IGU Configuration Examples

Hazardous Location Window (Standard Safety):

- Dual-pane IGU with interior tempered lite + exterior annealed lite

- Meets code requirements for safety glass

- Cost-effective solution for doors and low windows

Noisy Street-Facing Window (Acoustic Performance):

- Dual-pane IGU with exterior laminated lite + interior tempered lite

- Reduces traffic noise significantly (STC ~35+)

- Meets safety requirements while enhancing comfort

High-Security Application:

- Both lites constructed with laminated glass

- Maximum penetration resistance

- Post-breakage barrier on both sides

- Premium solution for vulnerable entry points

Low-E Coatings: Maximizing Energy Efficiency

Low-Emissivity (Low-E) coatings are microscopically thin, transparent metallic layers applied to the glass surface inside the IGU. These coatings work by reflecting infrared light (heat) while allowing visible light to pass through. Performance Benefits:

- Can reduce energy loss through windows by 30-50% according to the U.S. Department of Energy

- Keeps heat inside during Pacific Northwest winters

- Reduces cooling costs in summer by reflecting exterior heat

- Does not significantly darken the glass or reduce natural light

Climate-Specific Application: In the Portland and Vancouver area’s cool, rainy climate, Low-E coatings help retain interior heat during the long winter months, reducing heating costs and improving comfort. During summer, they prevent excessive solar heat gain, keeping homes cooler without relying heavily on air conditioning.

Why This Matters: Glass as an Integrated System

The glass in your home is not just a collection of individual panes—it’s an integrated system designed to work together. Modern windows combine:

- The right glass types for safety and security

- Low-E coatings for energy efficiency

- Proper gas fills (argon or krypton) for insulation

- Quality spacer systems to prevent seal failure

When you work with Town & Country Glass, we don’t just replace glass—we design complete window systems optimized for your specific needs, climate, and budget. This systems approach ensures you get maximum performance and value from your investment.

Key Takeaways

Choosing the right glass for your home is far more than an aesthetic decision—it’s a critical investment in your family’s safety, comfort, and long-term home value. As we’ve explored, annealed, tempered, and laminated glass each serve distinct purposes, and modern building codes exist specifically to ensure homeowners make informed, code-compliant choices.

Essential Points to Remember:

Tempered glass is the minimum standard for all doors, bathrooms, and low windows—it’s both a legal requirement and a proven safety solution. The 16 CFR Part 1201 safety standard and IBC Section 2406.4 exist because of documented injuries and deaths from broken annealed glass. Compliance protects your family and ensures your home passes inspection during sale.

Laminated glass delivers premium performance when security, noise reduction, UV protection, or overhead safety are priorities. While it costs more upfront, it’s an investment that pays dividends in livability, interior preservation, and peace of mind. For Pacific Northwest homeowners dealing with rain, storms, and noise, laminated glass often represents the best long-term value.

Annealed glass has limited modern applications but remains useful in protected, non-hazardous locations when properly paired with safety glass in IGU configurations. Understanding where it can and cannot be used is essential for code compliance.

Modern windows are integrated systems combining different glass types with Low-E coatings and proper construction to optimize safety, energy efficiency, and comfort. Working with knowledgeable professionals ensures these systems are designed correctly for your specific needs.

For Portland and Vancouver area homeowners, understanding these distinctions empowers you to work confidently with contractors, ensure code compliance, and optimize your home’s performance. Whether you’re replacing a single window or planning a whole-home renovation, the glass you choose will impact your daily life for decades to come.

Ready to ensure your home has the right glass for safety, efficiency, and comfort?

Contact Town & Country Glass for a professional consultation. Our team is extensively trained in building codes, glass performance, and custom fabrication—we’ll help you make the best choice for your specific needs and ensure proper installation that meets all safety standards.

References:

- Pilkington. (n.d.). The Float Process. Retrieved from https://www.pilkington.com/en/global/about/education/the-float-process

- National Safety Council. (2020). Injury Facts – Unintentional Injuries. Retrieved from https://injuryfacts.nsc.org/all-injuries/deaths-by-demographics/unintentional-injuries/

- North American Contractor Certification. (n.d.). A Look at Glass Tempering. Architectural Glass & Metal Certification Council. Retrieved from https://www.naccprogram.com/a-look-at-glass-tempering/

- Fenestration and Glazing Industry Alliance (FGIA). (n.d.). Tempered Glass Basics. Retrieved from https://fgiaonline.org/news/tempered-glass-basics

- U.S. Consumer Product Safety Commission. (n.d.). Code of Federal Regulations, Title 16, Part 1201 – Safety Standard for Architectural Glazing Materials. Retrieved from https://www.ecfr.gov/current/title-16/chapter-II/subchapter-B/part-1201

- International Code Council. (n.d.). 2021 International Building Code (IBC) – Section 2406: Safety Glazing. Retrieved from https://codes.iccsafe.org/content/IBC2021P2/chapter-24-glass-and-glazing

- Eastman Chemical Company. (n.d.). What is Laminated Glass?. Saflex.com. Retrieved from https://www.saflex.com/what-laminated-glass

- U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy. (n.d.). Update or Replace Windows. Retrieved from https://www.energy.gov/energysaver/update-or-replace-windows

- Grand View Research. (2021). Laminated Glass Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/laminated-glass-market

- Soundproof Windows, Inc. (n.d.). STC Ratings. Retrieved from https://www.soundproofwindows.com/stc-ratings/

- National Safety Council. (2022). Injury Facts – Falls. Retrieved from https://injuryfacts.nsc.org/home-and-community/home-and-community-overview/falls/

- Vitro Architectural Glass. (2017). Technical Document TD-138: Glass and Bending. Retrieved from https://www.vitroglazings.com/media/1058/td-138.pdf

- National Glass Association. (n.d.). What is Heat-Treated Glass?. Retrieved from https://www.glass.org/glass-informational-resources/what-heat-treated-glass

- Scientific Glass Laboratories, Inc. (n.d.). Spontaneous Breakage of Tempered Glass. Retrieved from https://sglinc.com/spontaneous-breakage-of-tempered-glass/

- Kuraray. (n.d.). SentryGlas® Ionoplast Interlayer. Retrieved from https://www.kuraray.com/products/sentryglas

- MarketsandMarkets. (2023). Security Glass Market – Global Forecast to 2028. Retrieved from https://www.marketsandmarkets.com/Market-Reports/security-glass-market-103134114.html

- WCONLINE. (2018). Understanding STC and OITC. Walls & Ceilings Magazine. Retrieved from https://www.wconline.com/articles/92339-understanding-stc-and-oitc

- Lawrence Berkeley National Laboratory, Windows & Daylighting Group. (n.d.). Low-E Coatings. Retrieved from https://windows.lbl.gov/low-e-coatings