Table of Contents

- Understanding Your Door: The Hidden Mechanics Behind That Smooth Glide

- Diagnosing the Problem: Why Your Sliding Glass Door Is Stuck

- Can You Fix It Yourself? A Realistic Guide to DIY vs. Professional Repair

- Case Study: How a $200 Repair Became a $2,500 Replacement

- Expert Service for Sliding Glass Doors in Portland and Vancouver

- Key Takeaways

If opening your sliding glass door feels like a full-body workout, you’re not alone. That frustrating grind and stick you experience every time you step outside isn’t just annoying—it’s a warning sign that something is failing in your door’s mechanical system. And ignoring it? That can turn a simple $200 repair into a $2,500 replacement nightmare.

Here’s what makes this more than just an inconvenience: approximately 60% of new single-family homes feature patio access via sliding glass doors, making this a widespread homeowner concern. But beyond the daily frustration, a malfunctioning door affects your home’s security, energy efficiency, and safety. The U.S. Consumer Product Safety Commission tracks thousands of emergency room visits annually related to door and window injuries, many from DIY repair attempts gone wrong.

This guide will help you understand what’s failing, why it’s happening, and—most importantly—when a professional repair will save you time, money, and potential injury. If you’re in the Portland or Vancouver area, the Pacific Northwest’s moisture-rich climate accelerates wear on door components, making proactive maintenance especially critical for local homeowners.

Understanding Your Door: The Hidden Mechanics Behind That Smooth Glide

Before you can fix a problem, you need to understand what you’re dealing with. Your sliding glass door isn’t just a piece of glass on a track—it’s a precision-engineered system where one failing part can trigger a cascade of problems.

Modern sliding doors have evolved dramatically from the lightweight, single-pane aluminum models of decades past. Today’s double- and triple-pane insulated glass units (IGUs) can make a single door panel weigh 80–150 pounds—a significant load borne entirely by small rollers at the base of the door. This evolution toward energy efficiency has created new mechanical stresses that homeowners need to understand.

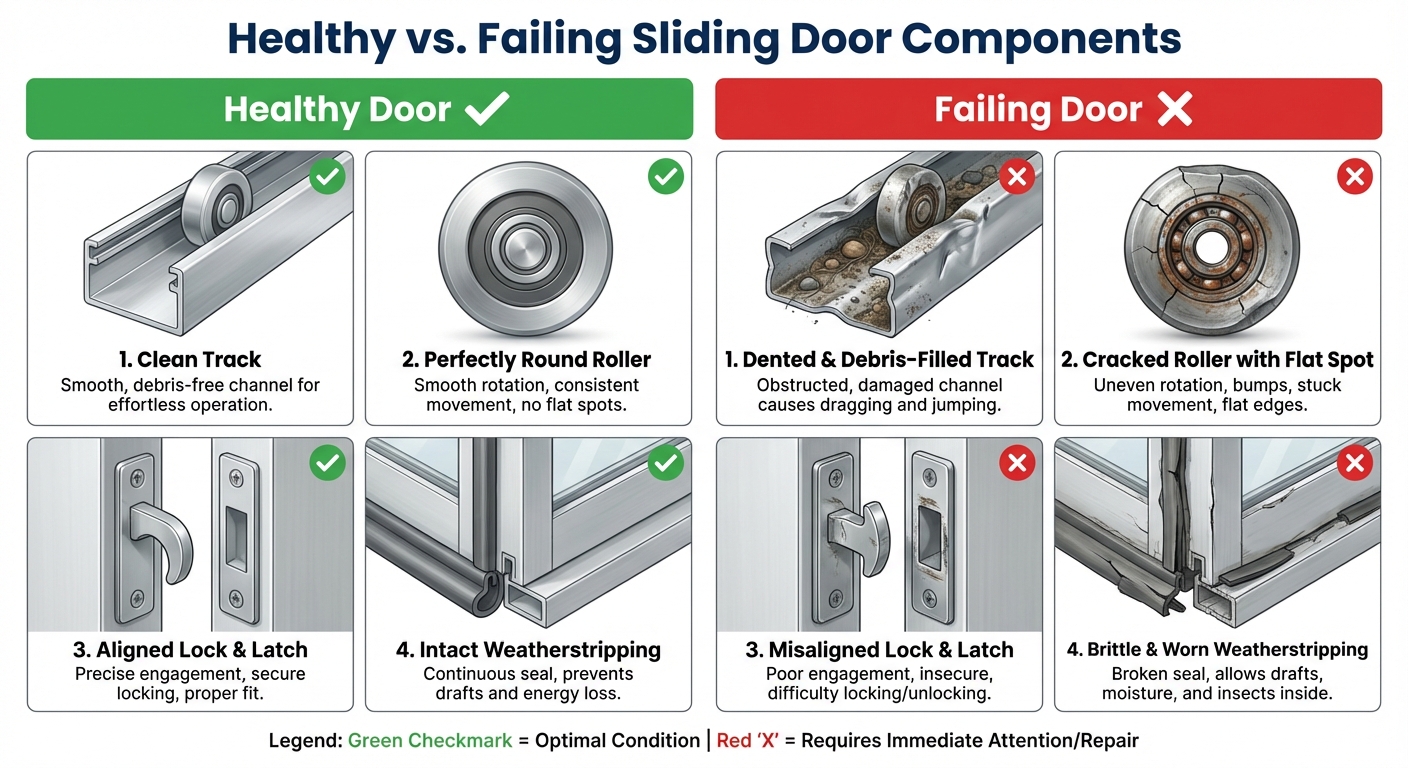

The Critical Components:

Rollers: These are the unsung heroes of your door system—and the most common failure point. Made from materials like nylon, acetal, or steel, each type has trade-offs in load capacity, corrosion resistance, and longevity. Nylon rollers are quiet and corrosion-resistant but can develop flat spots under constant weight. Steel rollers offer superior strength but can rust and seize in moisture-rich environments like the Pacific Northwest, grinding into your track and causing permanent damage.

Track: The aluminum or stainless steel rail that guides movement must remain perfectly clean and straight. Even a small dent can derail smooth operation. The U-shaped profile of most tracks makes them a natural collection point for dirt, pet hair, and small debris—creating the grinding sensation you feel when you try to open the door.

Frame and Glass: The structural housing supports the heavy IGU that provides insulation and soundproofing. This weight puts tremendous stress on the roller system, especially in doors that haven’t been properly maintained.

Lock Mechanism: A mortise lock inside the door frame must align perfectly with the strike plate on the jamb to function. When the door sags due to worn rollers, this alignment fails—leaving your home vulnerable.

Weatherstripping: Pile or foam seals prevent drafts and water intrusion, but they wear down from UV exposure and friction over time. Degraded seals don’t just let in cold air—they can also create additional drag that makes your door harder to move.

How Roller Materials Compare

Understanding which roller type your door uses helps predict failure patterns:

| Material | Load Capacity | Corrosion Resistance | Common Failure Mode | Best For |

|---|---|---|---|---|

| Nylon | Moderate | Excellent | Cracking, flat spots | Standard weight doors |

| Acetal | Moderate-High | Excellent | Cracking under extreme loads | Heavier residential doors |

| Steel (Uncoated) | Very High | Poor | Rusting, seizing, track abrasion | Dry climates only |

| Stainless Steel | Very High | Excellent | Bearing failure from debris | Heavy-duty doors, coastal areas |

Diagnosing the Problem: Why Your Sliding Glass Door Is Stuck

Understanding what’s wrong is the first step toward fixing it. Let’s break down the four most common culprits behind that stubborn, grinding door.

Worn or Broken Rollers: The #1 Culprit

If your door is hard to move, there’s a 90% chance the rollers are to blame. These small components carry the entire weight of your glass panel every single day, and over time, physics wins.

Plastic rollers develop flat spots or crack under constant load—a phenomenon called “creep deformation” where the material slowly deforms under sustained pressure. Metal rollers face a different enemy: corrosion. In the Pacific Northwest’s damp climate, uncoated steel rollers can rust and seize, transforming from rolling bearings into grinding blocks that scrape permanent grooves into your track.

The American Society of Home Inspectors consistently identifies component failure in high-use items like door hardware as a top issue in home inspections. What starts as slightly increased resistance when opening your door gradually worsens until it feels like you’re dragging the door across sandpaper.

Warning Signs:

- Grinding or scraping sounds when moving the door

- Visible cracks or flat spots on the rollers

- The door panel sitting lower on one side

- The door catching or sticking at certain points along the track

Dirty, Damaged, or Misaligned Tracks

Even brand-new rollers can’t save a compromised track. The U-shaped channel design that guides your door also acts as a perfect trap for dirt, pet hair, small rocks, and other debris. Each time you open the door, this grit gets compressed between the rollers and track, accelerating wear on both components.

But dirt isn’t the only problem. The soft aluminum used in most door tracks can be easily dented by impact—stepping on it while cleaning, bumping it with furniture, or damage from seized rollers grinding against it. Once the track develops grooves or dents, even new rollers will struggle to move smoothly.

There’s another factor particularly relevant to Pacific Northwest homeowners: foundation settling. The clay-rich soils common in Portland and Vancouver are prone to shrink-swell cycles with moisture changes. The U.S. Geological Survey notes this can cause gradual foundation movement that knocks door frames out of square over time, making proper alignment nearly impossible to maintain.

Warning Signs:

- Visible debris buildup in the track channel

- Dents, grooves, or discoloration in the track

- The door visibly off-square in the frame

- One corner of the door dragging more than others

Lock and Latch Malfunctions

Here’s something many homeowners don’t realize: that lock that won’t engage isn’t necessarily broken—it might be a symptom of door sag from worn rollers. When the door drops even a fraction of an inch, the latch no longer aligns with the strike plate on the jamb. You can turn the handle, but the mechanism has nothing to catch.

Internal lock components can also corrode or wear out from repeated use. But regardless of the cause, a lock you can’t engage is a serious security vulnerability. According to the Bureau of Justice Statistics, approximately 6.6% of household burglaries occur through unlocked sliding glass doors. A malfunctioning lock creates a persistent weak point that determined intruders can easily exploit.

Warning Signs:

- Difficulty turning the lock or handle

- The latch visibly missing the strike plate

- A loose or wobbly handle

- The lock engaging but not feeling secure

Degraded Weatherstripping and Seals

While weatherstripping might seem like a minor component, its failure has major consequences. UV radiation from sunlight breaks down seal polymers over time, making them brittle and ineffective. The constant friction of opening and closing wears away pile weatherstripping. Compressed seals lose their elasticity and can no longer spring back to create an airtight barrier.

The energy impact is significant. The U.S. Department of Energy estimates that air leaks through doors and windows account for up to 30% of heating and cooling energy use. Research from Lawrence Berkeley National Laboratory shows that sealing these leaks can reduce annual energy costs by 10–20%. A large sliding glass door with failed seals represents one of the biggest sources of energy waste in your home.

But there’s another concern: moisture intrusion. Failed seals allow rainwater to penetrate the door frame, potentially causing rot in wooden components or mold growth in wall cavities. In extreme cases, you might notice condensation forming between the glass panes—a sign that the IGU seal itself has failed.

Warning Signs:

- Visible daylight around the closed door

- Noticeable drafts when standing near the door

- Condensation or fog between glass panes

- Increased heating or cooling bills

- The door feeling harder to move due to seal drag

Can You Fix It Yourself? A Realistic Guide to DIY vs. Professional Repair

Let’s be honest: some maintenance tasks are perfect for a motivated homeowner, while others require professional expertise to avoid making things worse—or getting seriously hurt.

What You CAN Do Safely

Regular Track Cleaning: This is the single most effective preventive maintenance you can perform. Once a month (more often if you have pets or live near the coast), vacuum the track with a crevice tool attachment, then wipe it down with a damp cloth and mild cleaner. This removes the abrasive grit that accelerates roller wear.

Proper Lubrication: After cleaning, apply a silicone-based spray lubricant to the track and roller assemblies. The key word here is silicone—never use oil-based products like WD-40, which attract dirt and create a sticky residue that makes the problem worse. A light coating of silicone lubricant allows rollers to glide smoothly while repelling water and debris.

Minor Adjustments: Many sliding doors have adjustment screws accessible from the bottom or side of the panel. If your door has sagged slightly, you may be able to raise it by turning these screws clockwise. This can temporarily improve alignment and buy you time before a professional repair becomes necessary.

When to STOP and Call Town & Country Glass

Roller Replacement: This is where many homeowners get into trouble. Removing a 100+ pound glass panel is a two-person job that requires proper lifting technique and specialized tools. One wrong move can result in shattered glass, a cracked door frame, or serious back injury. Even if you successfully remove the door, identifying and sourcing the correct replacement rollers for your specific door model is nearly impossible without access to industry suppliers.

Track Repair or Replacement: Straightening a bent track or installing stainless steel track caps requires specialized tools and experience. Attempting this without proper equipment often causes more damage than it fixes.

Lock Repair: If simple adjustment doesn’t restore proper alignment, the internal mortise lock may be broken. Lock installation requires precision—improper installation compromises your home’s security and can void insurance claims if a break-in occurs through a poorly secured door.

Glass Replacement or Seal Failure: The Fenestration and Glazing Industry Alliance sets strict standards for glass installation to ensure safety and energy performance. Modern IGUs are heavy, fragile, and expensive. This is absolutely not a DIY task.

The Hidden Cost of DIY Gone Wrong

Here’s what happens when homeowners attempt repairs beyond their skill level: they drop and shatter expensive IGUs, crack door frames while trying to remove panels, sustain back injuries from improper lifting, or strip adjustment screws by using the wrong tools. What started as an attempt to save money on a $300 professional repair becomes a $2,500+ door replacement plus medical bills.

Professional technicians have the right tools, the right parts, and the right training to diagnose and fix your door safely and efficiently. That’s not just marketing—it’s the difference between a repair that lasts years and one that fails within weeks.

| Task | DIY? | What You Need | When to Call a Pro | Why Professional Service Matters |

|---|---|---|---|---|

| Track Cleaning | Yes | Vacuum, brush, mild cleaner | If track is bent or severely damaged | Professionals can assess if repair or replacement is needed |

| Lubrication | Yes | Silicone spray | If lubrication doesn’t help | Indicates deeper mechanical failure |

| Minor Adjustments | Maybe | Screwdriver | If door is extremely heavy or won’t adjust | Proper tools and leverage prevent injury |

| Roller Replacement | No | N/A | Always | Safe handling of heavy glass requires training and equipment |

| Lock Repair | Sometimes | Screwdriver | If lock is broken internally | Security depends on proper installation |

| Glass Replacement | No | N/A | Always | Industry standards ensure safety and energy performance |

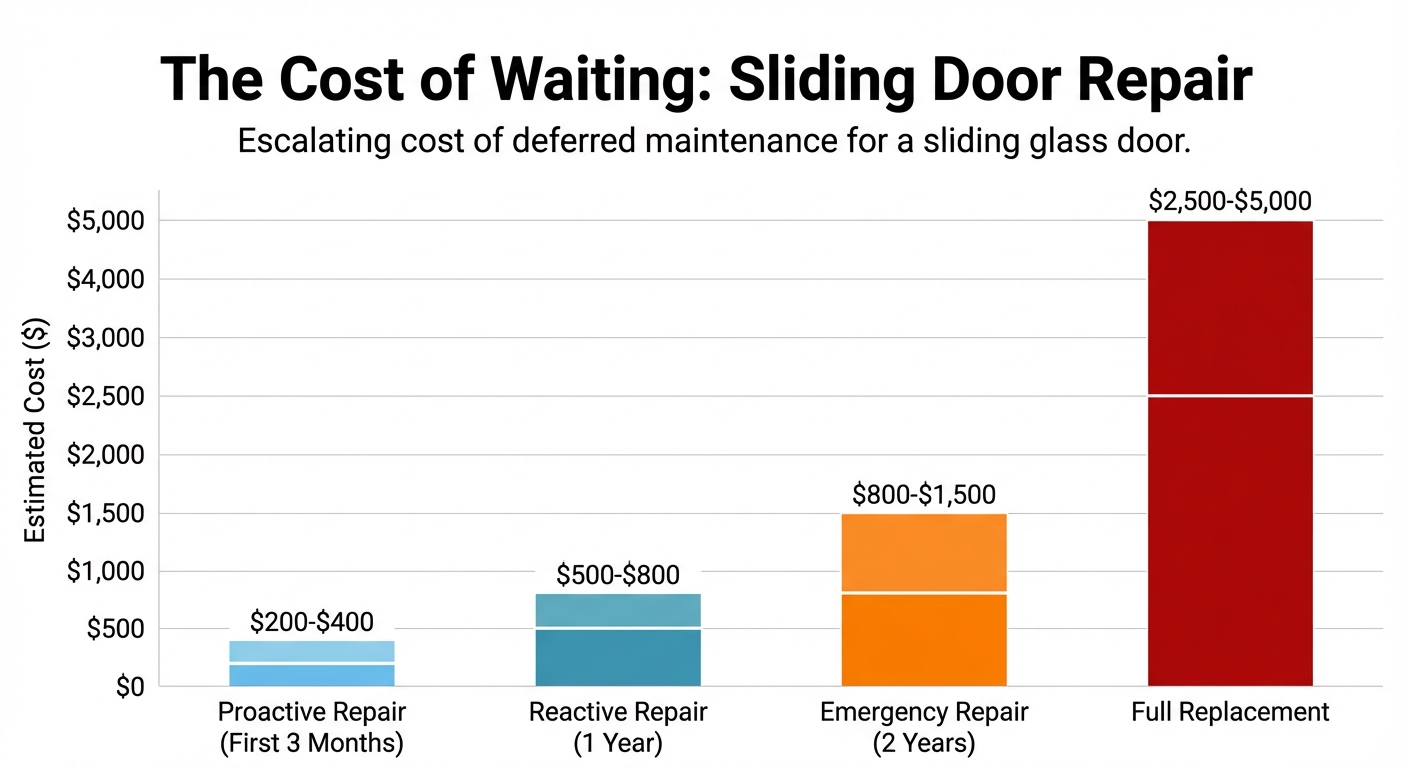

Case Study: How a $200 Repair Became a $2,500 Replacement

Let’s walk through a real-world scenario that plays out in Portland and Vancouver homes every year. A homeowner notices their 15-year-old sliding glass door becoming progressively harder to open. It’s annoying, but manageable—so they put off calling a professional.

Month 1–3: The Initial Problem

The original nylon rollers have developed flat spots from years of supporting a heavy, double-pane glass panel. The door requires slightly more effort to move, but it still functions. At this stage, a professional could replace the rollers for $200–$400—a simple, straightforward fix.

Month 6–12: Compounding Damage

Those failing rollers no longer roll smoothly—they grind along the aluminum track. This friction wears a groove into the track and puts additional stress on the door frame, causing a slight sag. The door is now very difficult to move, requiring significant force every time. The repair cost has increased to $500–$800 because now you need new rollers, a stainless steel track cap, and frame realignment.

Month 18–24: Secondary Failures

The sagging door no longer aligns with the jamb. The latch can’t engage with the strike plate, making it impossible to lock the door securely. The compromised alignment also damages the weatherstripping, creating a noticeable draft that increases winter heating bills. Air leaks that could have been prevented are now costing money every month.

Month 24: Catastrophic Failure

A family member attempts to force the stuck door open. A cracked roller shatters completely. The door drops onto the damaged track, lodging it in place and chipping the glass edge. The door is now inoperable and insecure. The emergency repair costs $800–$1,500+, or if the frame and glass are too damaged, a full door replacement runs $2,500–$5,000 or more.

The chart above illustrates this cost escalation clearly. What started as a simple roller replacement became a full door replacement because the problem was ignored. Every month of delay increased both the complexity and cost of the repair.

This isn’t just about money—it’s about security, energy efficiency, and safety. The U.S. Department of Housing and Urban Development notes that while a patio door’s expected lifespan is 20–30 years, individual hardware components have much shorter lives. Deferred maintenance can cut that hardware lifespan in half or more.

Expert Service for Sliding Glass Doors in Portland and Vancouver

When it comes to sliding glass door repair, regional expertise matters. Pacific Northwest homes face unique challenges that out-of-area contractors might not fully appreciate.

Why Local Knowledge Makes a Difference

The Pacific Northwest’s high moisture levels, clay-rich soils prone to seasonal settling, and occasional coastal salt air create environmental stressors that accelerate door component wear. Town & Country Glass understands these regional factors because we’ve been serving Portland and Vancouver homeowners since 1990.

We don’t just replace rollers and call it done. Our comprehensive diagnostic approach assesses track condition, frame alignment, seal integrity, and lock function to ensure a long-lasting repair. We’ve seen too many “quick fixes” fail within months because the underlying cause—misalignment from foundation settling, for example—wasn’t addressed.

Access to Quality Parts

Here’s something most homeowners don’t realize: sourcing the exact roller assembly for your door’s specific make, model, and year is incredibly difficult without industry connections. Manufacturers discontinue parts, change specifications, and use proprietary designs. We maintain relationships with suppliers and manufacturers to source hard-to-find components that keep older doors functioning smoothly.

Safety and Efficiency

Our trained technicians have the specialized tools and techniques to safely handle heavy IGU panels, preventing injury and glass damage. We’ve invested in proper lifting equipment, protective gear, and ongoing training to ensure every repair meets industry standards.

Transparent Pricing

We believe in upfront, honest pricing. Before we begin any work, you’ll receive a clear assessment and cost estimate. No hidden fees, no surprises—just professional service you can trust.

Ready to Get Your Door Gliding Smoothly Again?

Don’t let a minor inconvenience become a major expense. Contact Town & Country Glass for a professional assessment.

Key Takeaways

A sticky sliding glass door isn’t just annoying—it’s a sign of component failure that can cascade into expensive damage, energy inefficiency, and security vulnerabilities. The most common culprits—worn rollers, damaged tracks, failing locks, and degraded seals—follow predictable patterns of wear and tear, accelerated by the significant weight of modern energy-efficient glass.

Regular cleaning and lubrication can extend component life, but repairs like roller replacement, track restoration, and lock service require professional expertise. The weight of modern glass panels and the precision required for proper alignment make DIY repairs risky, often ineffective, and potentially dangerous.

Addressing these issues early with a qualified professional like Town & Country Glass saves you money, protects your home’s security, and restores the smooth, effortless operation your door was designed to provide. Don’t let a minor inconvenience become a major expense—if your sliding glass door is fighting back, it’s time to call in the experts.

Ready to fix that stubborn door? Contact Town & Country Glass today for fast, reliable service across Portland and Vancouver. Visit https://tandcglass.com/ or call 503-213-9737 to get started.

References:

- National Association of Home Builders (NAHB). (2022). What Home Buyers Really Want, 2022 Edition. https://www.nahb.org/news-and-economics/press-releases/2022/03/patios-are-in-and-so-are-front-porches

- National Fenestration Rating Council (NFRC). (2021). Understanding NFRC Ratings. https://www.nfrc.org/what-we-do/nfrc-ratings/

- Glass Association of North America (GANA). (2015). GANA Glazing Manual, 50th Anniversary Edition.

- ASM International. (2018). Corrosion of Aluminum and Aluminum Alloys. ASM Handbook, Volume 13C. https://www.asminternational.org/materials-resources/results/-/journal_content/56/10192/06446G/PUBLICATION

- Roylance, D. (2008). Mechanical Properties of Materials. Department of Materials Science and Engineering, Massachusetts Institute of Technology (MIT). https://ocw.mit.edu/courses/3-11-mechanics-of-materials-fall-1999/pages/modules/

- American Society of Home Inspectors (ASHI). Standard of Practice for Home Inspections. https://www.homeinspector.org/Standards-of-Practice

- U.S. Department of Housing and Urban Development (HUD). (2007). Residential Rehabilitation, Inspection Guide, Cost Estimator, and Specifications. https://www.huduser.gov/portal/publications/destech/RRGuide.html

- U.S. Geological Survey (USGS). (2016). Swelling Clays Map of the Conterminous United States. https://www.usgs.gov/media/images/swelling-clays-map-conterminous-united-states

- Bureau of Justice Statistics (BJS). (2019). National Crime Victimization Survey, 2018. https://bjs.ojp.gov/library/publications/household-burglary-1994-2018

- American Chemical Society. (2014). Polymers and UV Radiation. https://www.acs.org/education/resources/highschool/chemmatters/past-issues/2013-2014/october-2013/polymers-and-uv-radiation.html

- U.S. Department of Energy. Energy Saver: Air Sealing Your Home. https://www.energy.gov/energysaver/air-sealing-your-home

- Lawrence Berkeley National Laboratory (LBNL). (2019). Residential Building Air Leakage. https://res-air.lbl.gov/

- U.S. Consumer Product Safety Commission (CPSC). (2022). National Electronic Injury Surveillance System (NEISS) Data Highlights. https://www.cpsc.gov/Research–Statistics/NEISS-Injury-Data

- Fenestration and Glazing Industry Alliance (FGIA). FGIA Publication Store. https://fgiaonline.org/store

- U.S. Department of Energy. (2023). Qualifying Products: Sliding Glass Doors. ENERGY STAR Program. https://www.energystar.gov/products/sliding_glass_doors