Table of Contents

- The Science Behind Insulated Glass Units (and Why They Fail)

- How Much Are Failed Window Seals Costing Portland Homeowners?

- Debunking Window Repair Myths: What Works (and What Wastes Your Money)

- Should You Replace the Glass or the Whole Window? A Practical Decision Guide

- Getting It Right: Quality Standards and Professional Installation

Have you noticed condensation, fog, or even mineral deposits appearing between the panes of your double-pane windows—no matter how much you clean them? This frustrating issue is more than just a cosmetic problem. It’s a clear sign that your window’s Insulated Glass Unit (IGU) has failed, and it’s quietly costing you money every month through lost energy efficiency. For Portland homeowners, where cool, wet winters demand reliable heating and summer comfort depends on keeping heat out, a failed window seal can increase your energy bills by $20-$55 per year—per window. When multiple windows fail (which often happens as they age together), these costs multiply quickly. According to the U.S. Department of Energy, windows are responsible for 25-30% of residential heating and cooling energy use, and in the Pacific Northwest, that figure can reach as high as 39%. In this guide, we’ll explain exactly what’s happening inside your foggy windows, why it matters, how much it’s costing you, and—most importantly—why replacing just the glass unit is often a smarter, more affordable solution than replacing the entire window. Let’s clear up the confusion around foggy windows once and for all.

The Science Behind Insulated Glass Units (and Why They Fail)

Understanding how modern double-pane windows work—and what goes wrong—is essential to making an informed repair decision.

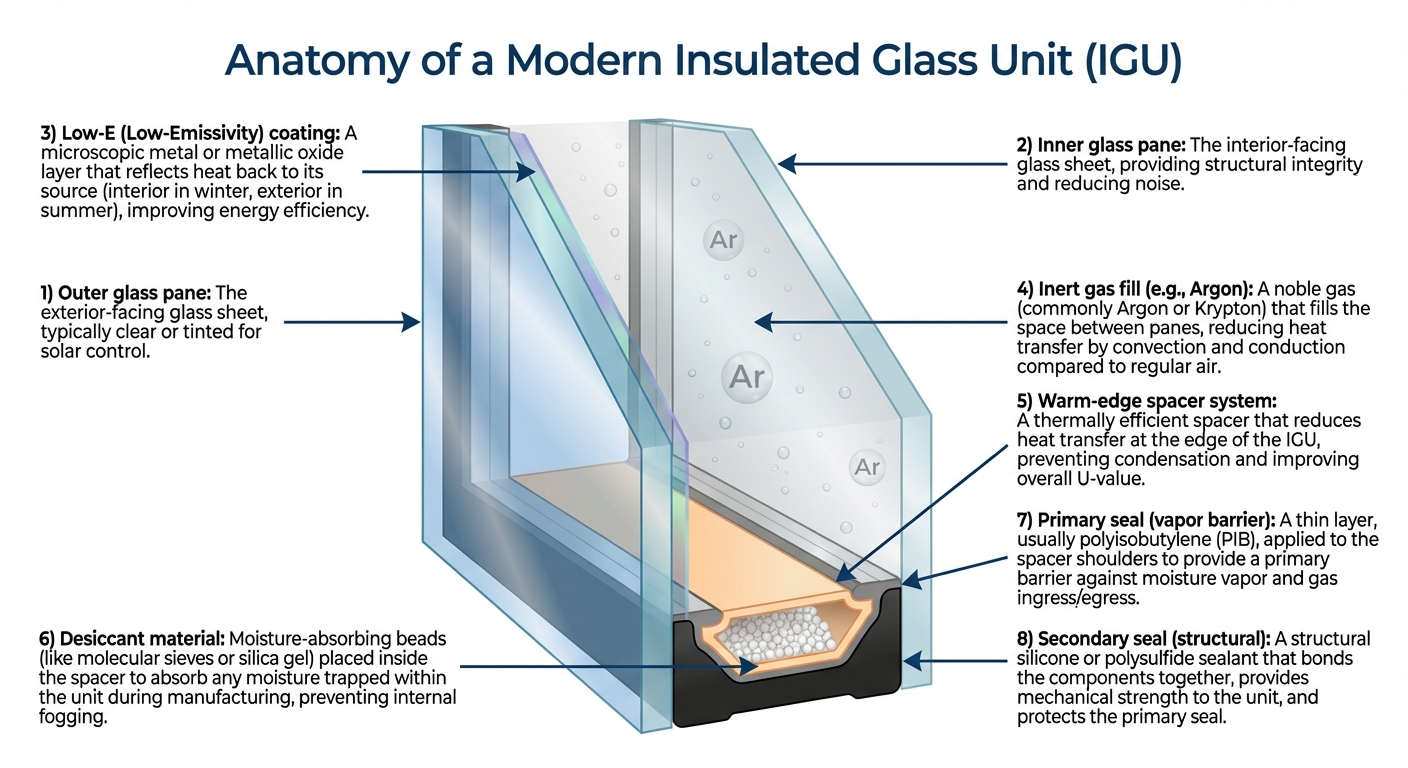

Modern windows are sophisticated systems, not just two panes of glass. A typical IGU includes several critical components working together to provide superior insulation: Low-E coated glass reflects heat back into your home in winter and blocks solar heat in summer, improving energy efficiency by up to 50% compared to single-pane windows. This microscopically thin metallic coating is applied to one or more glass surfaces and comes in two types: hard-coat (pyrolytic) and soft-coat (sputtered), with soft-coat being more common in residential applications due to its superior performance. Argon or krypton gas fill between the panes is significantly denser than air, which slows heat transfer through the window. Argon is the most common and cost-effective choice, while krypton provides even better insulation in narrower spaces, making it ideal for triple-pane units. A spacer system separates the glass panes and creates a uniform space between them. Modern “warm-edge” spacers made from stainless steel, structural foam, or thermoplastic composites reduce heat transfer at the window’s edge by up to 5% and can increase edge temperature by as much as 15°F—significantly minimizing condensation risk compared to traditional aluminum spacers. The spacer contains a moisture-absorbing desiccant, typically silica gel or molecular sieve, whose sole purpose is to absorb any residual moisture trapped during manufacturing, ensuring a completely dry, fog-free space for the life of the unit. A dual seal system is crucial for longevity. The primary seal (often polyisobutylene, or PIB) acts as a vapor barrier preventing moisture entry and gas escape. The secondary seal (typically silicone, polysulfide, or polyurethane) provides structural strength, holding the entire unit together and adding an extra layer of protection.

How Seal Failure Happens

Seal failure occurs in two distinct stages, and understanding this progression explains why you didn’t notice a problem until fog appeared: Stage One (invisible): Microscopic seal breaches allow the insulating argon gas to slowly escape and be replaced by regular air. The Fenestration and Glazing Industry Alliance (FGIA) standard allows up to 1% gas leakage per year; anything higher indicates premature failure. During this stage, your window’s performance degrades by 30-50%, but you won’t see any visible signs yet. Your energy bills are already increasing, but the problem remains hidden. Stage Two (visible): As the seal deteriorates further, water vapor penetrates the unit. The desiccant becomes saturated and can no longer absorb incoming moisture. Water vapor then condenses on the interior glass surfaces—this is the fog you see. In advanced cases, mineral deposits etch the glass permanently as trapped water repeatedly evaporates and re-condenses, leaving a cloudy haze that can never be cleaned.

What Causes Seals to Fail?

Several environmental and physical factors stress window seals over time:

- Thermal pumping (also called solar pumping) creates constant stress on seals. Daily cycles of solar heating and nighttime cooling cause the gas inside to expand and contract, creating pressure differentials that make the glass panes flex slightly. This repetitive motion gradually weakens the seal materials.

- UV radiation from direct sunlight degrades the organic compounds in sealant materials over years of exposure, making them brittle and prone to cracking.

- Water exposure accelerates deterioration. Poor drainage or clogged weep holes allow water to pool against the window frame, saturating the unit’s edge and breaking down the secondary sealant.

- Manufacturing or installation defects can cause premature failure. A flawed factory seal or improper installation that puts undue pressure on the glass unit compromises the system from the start.

Quality IGUs typically last 15-25 years, though many last longer with proper installation and maintenance. However, once seal failure begins, it’s irreversible and will only get worse.

How Much Are Failed Window Seals Costing Portland Homeowners?

Foggy windows aren’t just an eyesore—they represent a measurable, ongoing financial penalty and comfort loss that compounds every heating and cooling season.

The Immediate Energy Efficiency Penalty

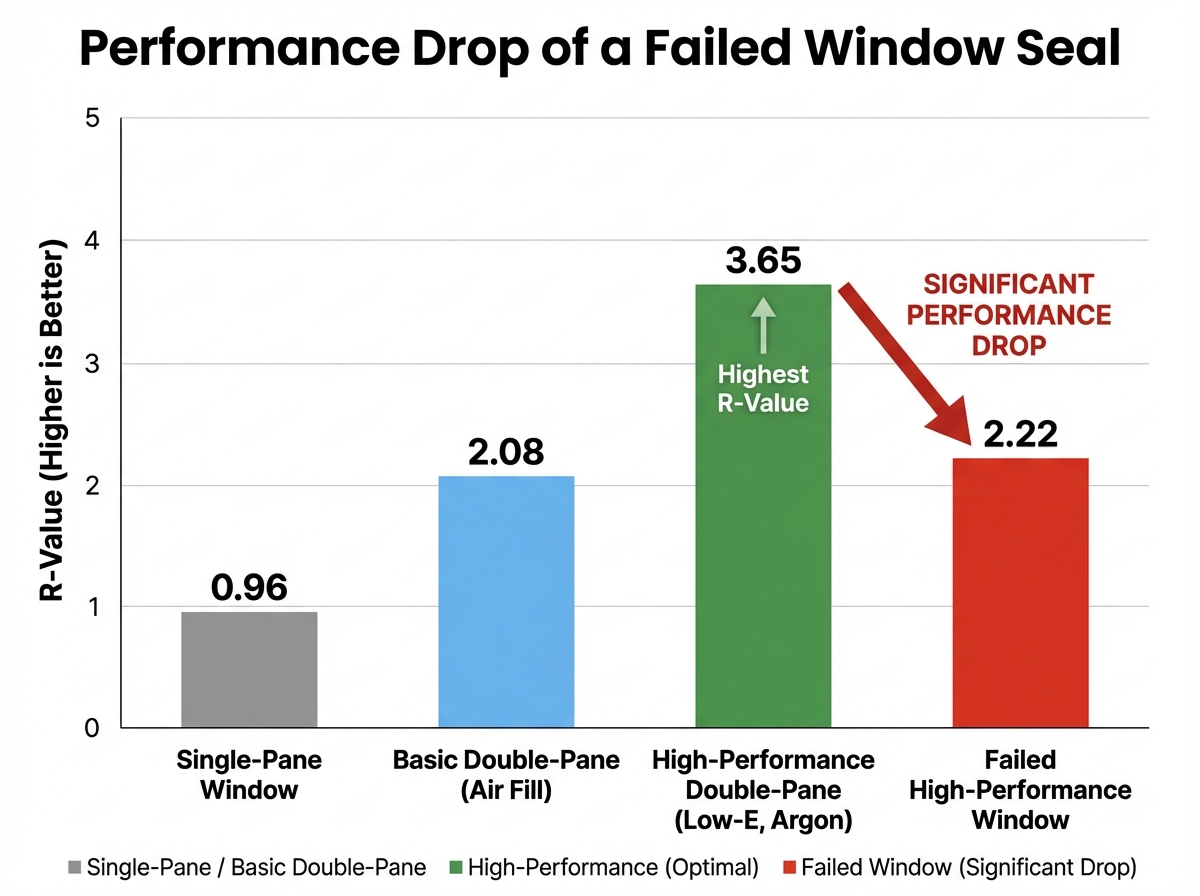

When a high-performance, argon-filled, Low-E window fails, its thermal performance (measured by U-factor) degrades by 30-50%, reverting to nearly the performance level of a basic air-filled double-pane window from the 1980s. A window that was designed to keep your home comfortable and efficient is now performing like outdated technology—yet you’re still relying on it every day.

Portland’s Climate Makes This Worse

Portland is located in ENERGY STAR Climate Zone 4C (Marine)—characterized by cool, wet winters requiring significant heating. The Northwest Energy Efficiency Alliance reports that windows can account for up to 39% of a home’s heating loss in the Pacific Northwest, far exceeding the national average. With Oregon’s average residential electricity rate at 13.01 cents per kWh (as of late 2023), a single failed 3’x5′ window costs an extra $20-$55 annually in heating and cooling. While this might seem modest for one window, consider that windows installed during the same construction period often fail around the same time.

Beyond Energy Costs: The Total Impact

- Comfort loss is immediate and noticeable. Failed windows create cold spots and drafts in winter, making rooms uncomfortable even when your heating system is working overtime. They also lose their ability to block solar heat in summer, leading to hotter rooms and overworked air conditioning.

- UV protection degradation means you’re missing the opportunity to protect your home. High-performance Low-E coatings block up to 99% of harmful UV radiation that fades furniture, flooring, and artwork. While the coating doesn’t disappear when seals fail, addressing the issue gives you the chance to restore this protection.

- Condensation risk extends beyond the window itself. Severely degraded windows can contribute to interior condensation, potentially causing mold or rot in surrounding wall structures—repairs that cost far more than replacing the glass units.

- Home value impact is real. Visible window failure signals deferred maintenance to potential buyers and home inspectors, potentially lowering your property’s market value or becoming a negotiating point that costs you thousands at closing.

The Research on Energy Savings

A Pacific Northwest National Laboratory study found that upgrading from older double-pane windows (similar in performance to failed high-performance windows) to ENERGY STAR-rated windows resulted in 10-20% annual heating and cooling savings in Portland’s climate zone. These savings are primarily derived from the IGU itself—meaning restoring window performance through glass replacement delivers measurable, documented energy conservation. The financial logic is clear: every month you delay addressing failed window seals, you’re paying an energy penalty that will never be recovered.

Debunking Window Repair Myths: What Works (and What Wastes Your Money)

When searching for solutions to foggy windows, homeowners often encounter misleading “quick fix” proposals. Here’s why these fail and what actually restores your window’s performance.

Myth #1: Windows Can Be “Defogged” by Drilling and Cleaning

Some companies offer a service that drills holes in the glass, sprays cleaning solution inside, and installs a one-way air valve. This approach is fundamentally flawed for several reasons:

- It does not repair the broken seals—the root cause of the problem. The microscopic breaches that allowed gas to escape and moisture to enter remain completely unaddressed.

- It permanently removes the insulating argon gas, which cannot be replenished through a drilled hole. This means you’ve now guaranteed your window will never perform at its designed efficiency level again.

- It can damage or etch the delicate Low-E coating during the cleaning process, further degrading the window’s thermal performance.

- The fog will return as moisture continues entering the unsealed unit. You’ve paid for a temporary cosmetic fix that doesn’t solve the underlying problem.

Myth #2: “It’s Just Cosmetic—I Can Live With It”

The visible fog is merely the final symptom of complete insulation failure. The financial penalty from energy loss began months or years before you saw the fog, during the invisible Stage One failure when argon gas was escaping. Every day you wait to address the problem, you’re paying extra on your energy bills. The longer you delay, the more money you lose—and unlike a repair investment, that lost money is gone forever.

Myth #3: “I Have to Replace the Entire Window”

This is the most expensive misconception and often the most unnecessary. In the vast majority of cases, the window frame, sash, and hardware remain in perfect condition. The IGU is a self-contained component specifically designed to be replaceable. Window frames—whether wood, vinyl, fiberglass, or aluminum—typically outlast the IGU by decades when properly maintained. Unless your frame shows rot, warping, structural damage, or operational problems, there’s simply no reason to replace it.

What Actually Works: IGU Replacement

The only effective solution is professional removal of the failed glass unit and installation of a brand-new, custom-measured IGU featuring:

- Fresh Low-E coating for maximum energy efficiency

- New argon gas fill at full concentration

- New factory seals engineered to last another 15-25 years

- Moisture-free space with new desiccant

Result: Full restoration of the window’s original energy efficiency and crystal-clear visibility—at a fraction of the cost of full window replacement.

Should You Replace the Glass or the Whole Window? A Practical Decision Guide

The right choice depends on the condition of your window frame. Here’s how to decide—and what each option really costs.

When IGU-Only Replacement Is the Right Choice

Choose glass-only replacement when:

- Your window frame and sash are structurally sound (no rot, cracks, or warping)

- Windows open, close, and lock properly

- You’re satisfied with the style and functionality

- Your primary goal is restoring energy efficiency cost-effectively

This applies to the majority of foggy window situations. Most frames remain in excellent condition long after the IGU has failed, making full window replacement both unnecessary and wasteful.

When Full Window Replacement Is Necessary

Replace the entire window system when:

- You observe visible frame rot, warping, or structural damage

- Windows are difficult or impossible to operate

- There’s evidence of water intrusion in the surrounding wall

- You desire a major aesthetic upgrade or change in window style (e.g., double-hung to casement)

Cost Comparison for Portland/Vancouver Area

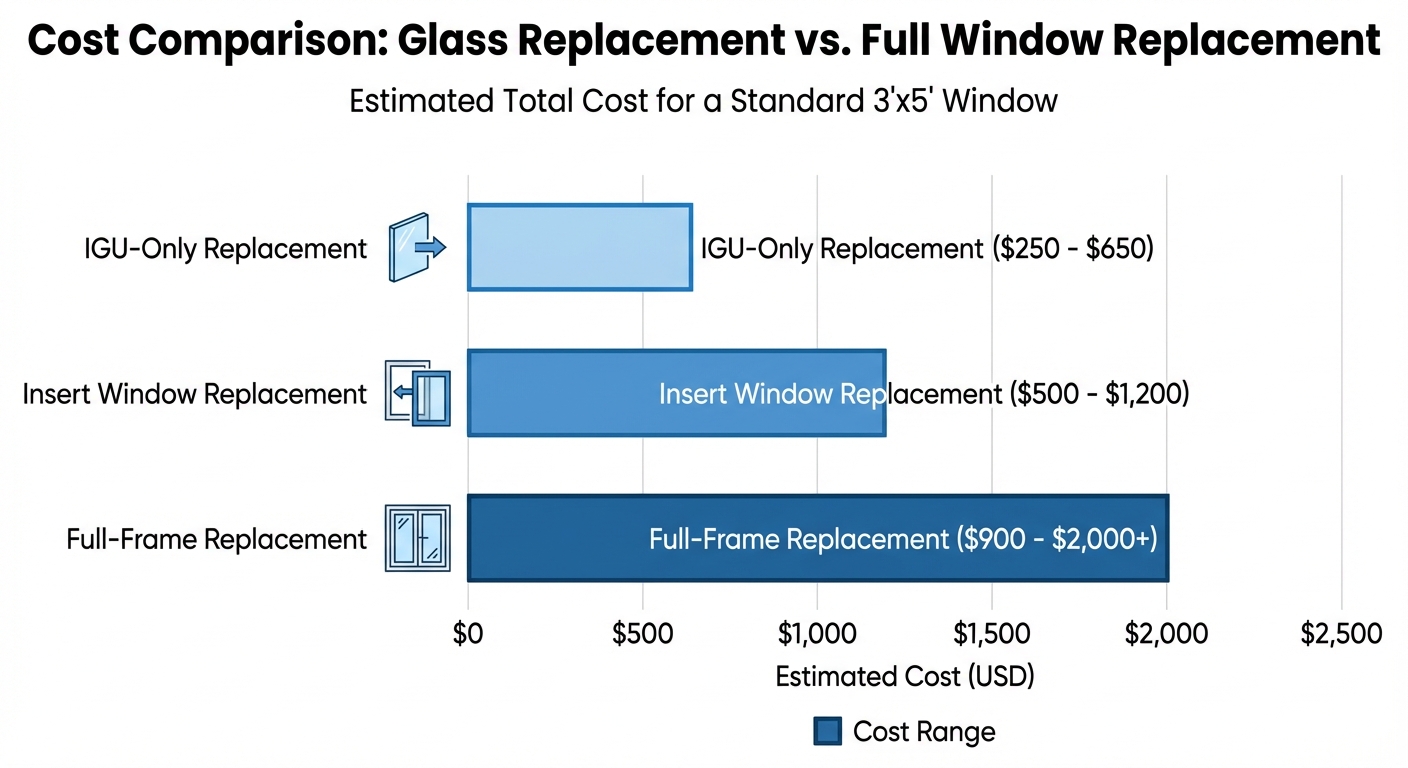

For a standard 3’x5′ window, here’s what you can expect to pay:

| Replacement Type | Material Cost | Labor Cost | Total Cost | Time Required |

|---|---|---|---|---|

| IGU Replacement | $150-$400 | $100-$250 | $250-$650 | 1-2 hours |

| Insert Window Replacement | $300-$800 | $200-$400 | $500-$1,200 | 2-4 hours |

| Full-Frame Replacement | $500-$1,200 | $400-$800+ | $900-$2,000+ | 4-8 hours |

These figures represent national cost data; local Portland market rates may vary. However, the proportional savings of IGU-only replacement remain consistent: you’ll typically save 50-75% compared to full window replacement.

Additional Benefits of IGU-Only Replacement

- Environmental sustainability: Replacing only the glass generates significantly less waste by reusing the entire window frame. This approach aligns with EPA principles of resource conservation and waste reduction—you’re making the environmentally responsible choice.

- Preserves character: In homes with custom, historic, or architecturally significant windows, glass-only replacement maintains the original aesthetics and design intent that define your home’s character.

- Faster turnaround: Less construction means less disruption to your home and daily life. Most IGU replacements are completed in a single visit.

- No exterior work: Because the frame isn’t touched, there’s no need to disturb siding, which eliminates related risks, costs, and the potential for mismatched materials if your siding is older.

Return on Investment

IGU replacement pays for itself through energy savings in 4-12 years, depending on the number of windows replaced and local energy costs. Full window replacement takes significantly longer to recoup costs unless the frame was already failing and would have required replacement anyway. When you factor in the avoided energy waste during the years you’d be waiting for a full replacement to pay off, glass-only replacement becomes even more financially attractive.

Getting It Right: Quality Standards and Professional Installation

Not all replacement IGUs are created equal. Here’s how to ensure you get a high-performance, long-lasting solution.

Demand Industry-Certified Glass

FGIA/IGCC/IGMA Certification is your guarantee of quality. The Fenestration and Glazing Industry Alliance runs rigorous testing programs for durability, seal integrity, and gas retention under harsh environmental conditions. These tests simulate years of thermal cycling, humidity exposure, and UV degradation. Always insist on certified IGUs—anything less is a gamble with your investment. NFRC ratings apply to complete window systems rather than individual IGUs, but the glass should still be manufactured to meet specific performance targets. For Portland’s Climate Zone 4C, look for these specifications:

- Target U-factor: 0.25-0.30 (lower numbers indicate better insulation)

- Target SHGC: 0.25-0.40 (lower numbers reduce unwanted solar heat gain)

- Warm-edge spacer system recommended (reduces condensation risk at glass edges by up to 15°F)

Professional Installation Is Non-Negotiable

Even the highest-quality IGU will fail prematurely if improperly installed. Professional installation ensures:

- Proper measurement: Custom-fit units prevent stress on seals that can cause premature failure.

- Correct support: Setting blocks properly distribute the glass weight, preventing edge seal damage.

- Frame preparation: The frame must be thoroughly cleaned, dried, and properly sealed to prevent water intrusion.

- Warranty protection: Professional installation is typically required to maintain manufacturer warranties. DIY installation almost always voids coverage.

Questions to Ask Your Glass Contractor

Before hiring anyone to replace your IGUs, ask:

- “Is the replacement IGU FGIA/IGCC certified?”

- “What is the U-factor and SHGC of the new glass?”

- “What type of spacer system is used?”

- “What warranty covers the new IGU, and what does it include?”

- “How long have you been performing IGU replacements, and can you provide local references?”

Red Flags to Avoid

Walk away from contractors who:

- Push “defogging” services as a permanent solution

- Are unwilling to provide manufacturer specifications or certifications

- Pressure you to replace entire windows when frames are clearly sound

- Make no mention of warranties or industry certifications

- Cannot explain the difference between various glazing options

A reputable glass professional will educate you about your options, provide transparent pricing, and stand behind their work with solid warranties.

Final Thoughts

Foggy windows are not a minor inconvenience—they’re a symptom of total insulation failure that’s costing you money every month and compromising your home’s comfort. The science is clear: once an IGU’s seal breaks, the insulating gas escapes, moisture intrudes, and thermal performance drops by up to 50%. Quick-fix “defogging” solutions fail to address the root cause and are explicitly not endorsed by industry organizations like FGIA. For the vast majority of Portland homeowners dealing with foggy windows, replacing only the Insulated Glass Unit is the smartest solution. It fully restores your window’s energy efficiency and clarity at a fraction of the cost and disruption of full window replacement—typically $250-$650 per window versus $900-$2,000+. When your window frames are still in good condition, there’s simply no reason to replace them. By choosing quality, FGIA-certified replacement glass and professional installation, you’ll stop the energy waste, eliminate the fog, restore your home’s comfort, and protect your investment for another 15-25 years. Don’t let failed window seals quietly drain your budget any longer.

Ready to Restore Your Windows’ Performance?

Contact Town & Country Glass for a free assessment and discover how affordable professional glass replacement can be.

References:

- U.S. Department of Energy. (n.d.). Update or Replace Windows. Energy.gov.

- U.S. Department of Energy. (n.d.). Energy Performance Ratings for Windows, Doors, and Skylights. Energy.gov.

- Northwest Energy Efficiency Alliance. (n.d.). Windows.

- Lawrence Berkeley National Laboratory. (n.d.). Gas-Filled Windows. Windows and Daylighting Group.

- U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy. (2015). Window Spacers. Building Technologies Office.

- Fenestration and Glazing Industry Alliance. (2019). Guidelines for the Production of IGCC®/IGMA® Certified Insulating Glass Units. FGIA Publication TM-4100-19.

- Wilson, A. G., & Solvason, K. R. (1962). Performance of Sealed Double-Glazing Units. National Research Council Canada.

- Van Den Bergh, W., Hart, R., Jelle, B. P., & Gustavsen, A. (2013). Window Spacers and Edge Seals in Insulating Glass Units: A State-of-the-Art Review and Future Perspectives. Energy and Buildings, 58, 263-280.

- ENERGY STAR. (n.d.). Climate Zone Map.

- U.S. Energy Information Administration (EIA). (2024). Electricity Data: Average price of electricity to ultimate customers by end-use sector.

- Pacific Northwest National Laboratory (PNNL). (2013). Field Performance of Low-E Storm Windows. PNNL-22442.

- Fenestration and Glazing Industry Alliance. (2011). Informational Bulletin Regarding the Process of In-Line Re-glazing of Previously Sealed Insulating Glass (IG) Units. FGIA Publication TB-1101-11.

- Forbes Home. (2024). How Much Does Window Replacement Cost?

- This Old House. (2024). Cost to Replace Window Glass.

- U.S. Environmental Protection Agency (EPA). (n.d.). Sustainable Marketplace: Greener Products and Services.

- National Fenestration Rating Council. (n.d.). Why NFRC Ratings Matter.